VitaGoat | SolarFlex | SoyaKit | Heat Pump Dryers | SoyCow

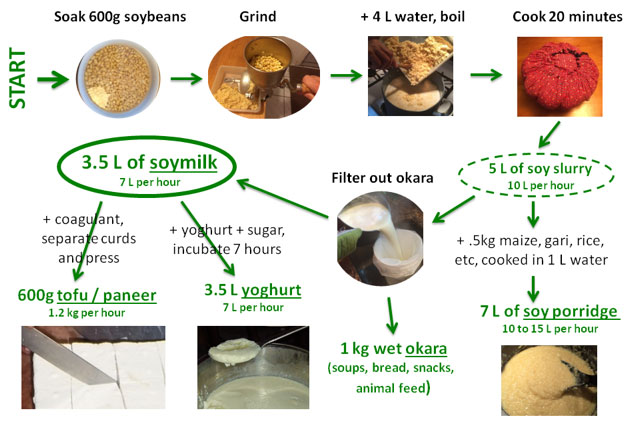

Malnutrition Matters offers plant-based sustainable food technology solutions and small business training directly to entrepreneurs and in partnership to NGO's / PVO's and small-scale commercial enterprises in developing countries by offering good-value food processing equipment from a number of sources internationally, mostly from developing countries. One principal focus is on the processing of soya, into an aqueous solution. This solution, or "soymilk", can then be consumed as a beverage, or further processed into a variety of other value-added products such as tofu, yogurt, spreads, puddings, etc. The fiber-rich "okara" residue from this process is available for breads, as additions to other foods, or can be used as animal feed.

A second focus is on food drying equipment. This equipment allows for the long-term preservation of fresh fruits, vegetables, herbs, and leaves without the use of chemical additives.

For a complete picture of MM’s capabilities, see the MM Capabilities Statement.

SoyCow / VitaGoat:

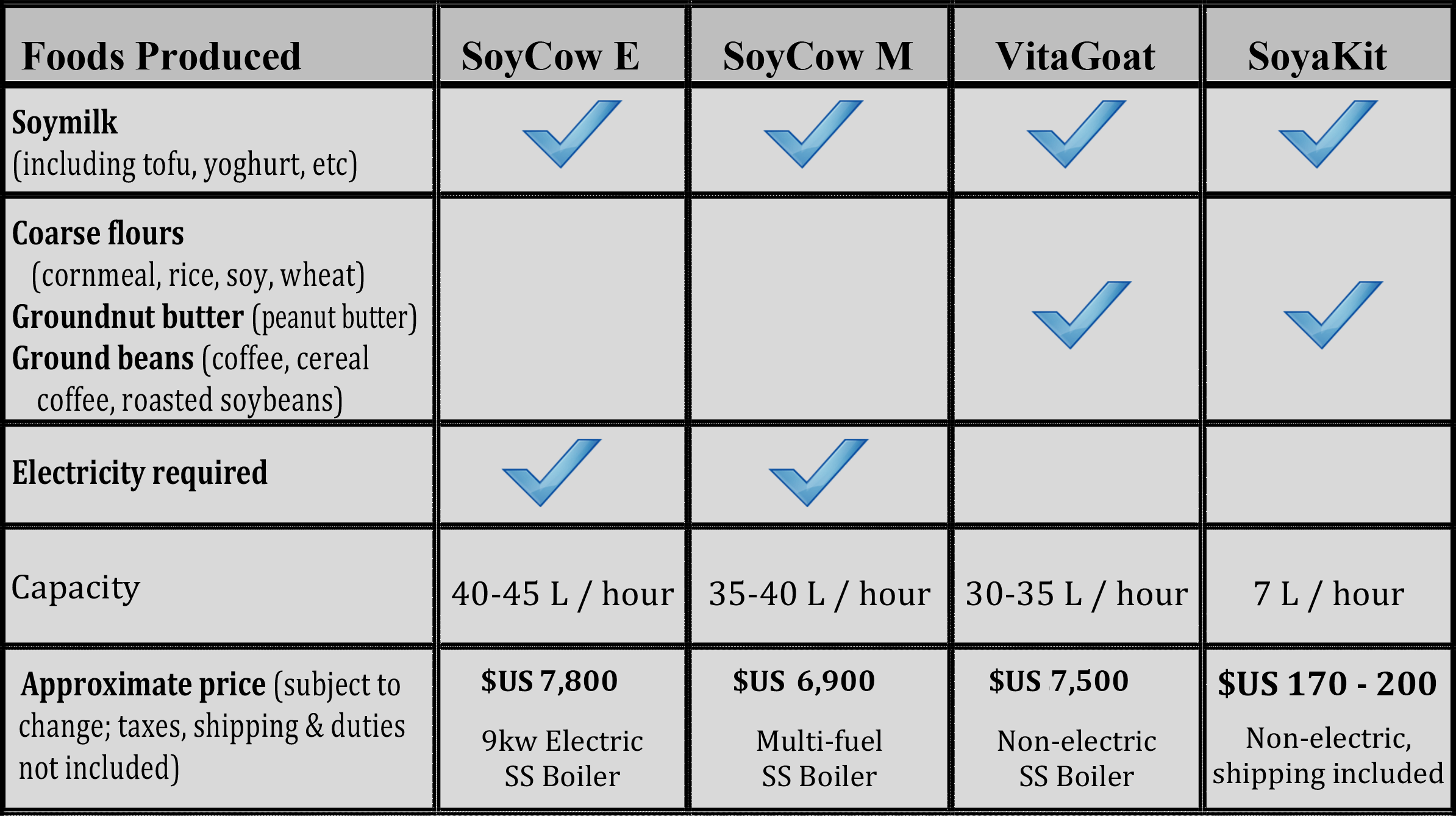

The primary production process involved is grinding and cooking the food with water and the subsequent extraction and/or separation of the products as necessary. There are two main types of equipment available: the SoyCow (models E and M), and the VitaGoat. The SoyCow systems (click on "SoyCow" for more details on both versions) require access to electricity for the electric grinder, and also for the electric boiler with the SoyCow E. The "VitaGoat" system does not require electricity or running water. It also allows both aqueous cooking/processing as well as dry grinding (cereals, grains, nuts).

The VitaGoat is suitable for village and rural environments, such as women's self-help groups and nutritional supplementation programs. SoyCow / VitaGoat Details

Other videos:

School-feeding and Business

Soy Dairy in Ghana

SoyCow 30

This is a higher capacity all-electric system featuring: Built-in grinder on cooker, up to 80 L/hr capacity (about double normal SoyCow), 18 kW electric boiler, semi or fully automatic, with stainless steel core. Details here

Food Dryers:

SolarFlex: Drying fruits and vegetables with this system is a cost-effective long-term food storage solution that requires no external electricity to operate. As a heat source, the system uses passive solar air collection. Fans, powered by a PV solar-charged battery, move the hot air through the drying chamber. The SolarFlex Small Farm model is available for $1,650. - $1,900. depending on quantity. Since no external electricity is required, these systems are also suitable for village and rural environments. SolarFlex Details

Heat Pump Dryers: Heat pump energy sourcing is known to be the least expensive use of electrical power. Several configurations are available. These can be with or without the drying cabinet and racks which could be built or sourced locally. They can also be with or without solar air pre-heating option. These are available in 3 HP capacity beginning under $4,000 and 6 HP capacity at under $6,000. For details click here.

VitaGoat | SolarFlex | SoyaKit | Heat Pump Dryers | SoyCow

Stay Up to Date

Questions?

Request more information from matters@malnutrition.org

© 2025 Malnutrition.org | Malnutrition Matters. All Rights Reserved.