SoyCow

home > our-technologies > soycow

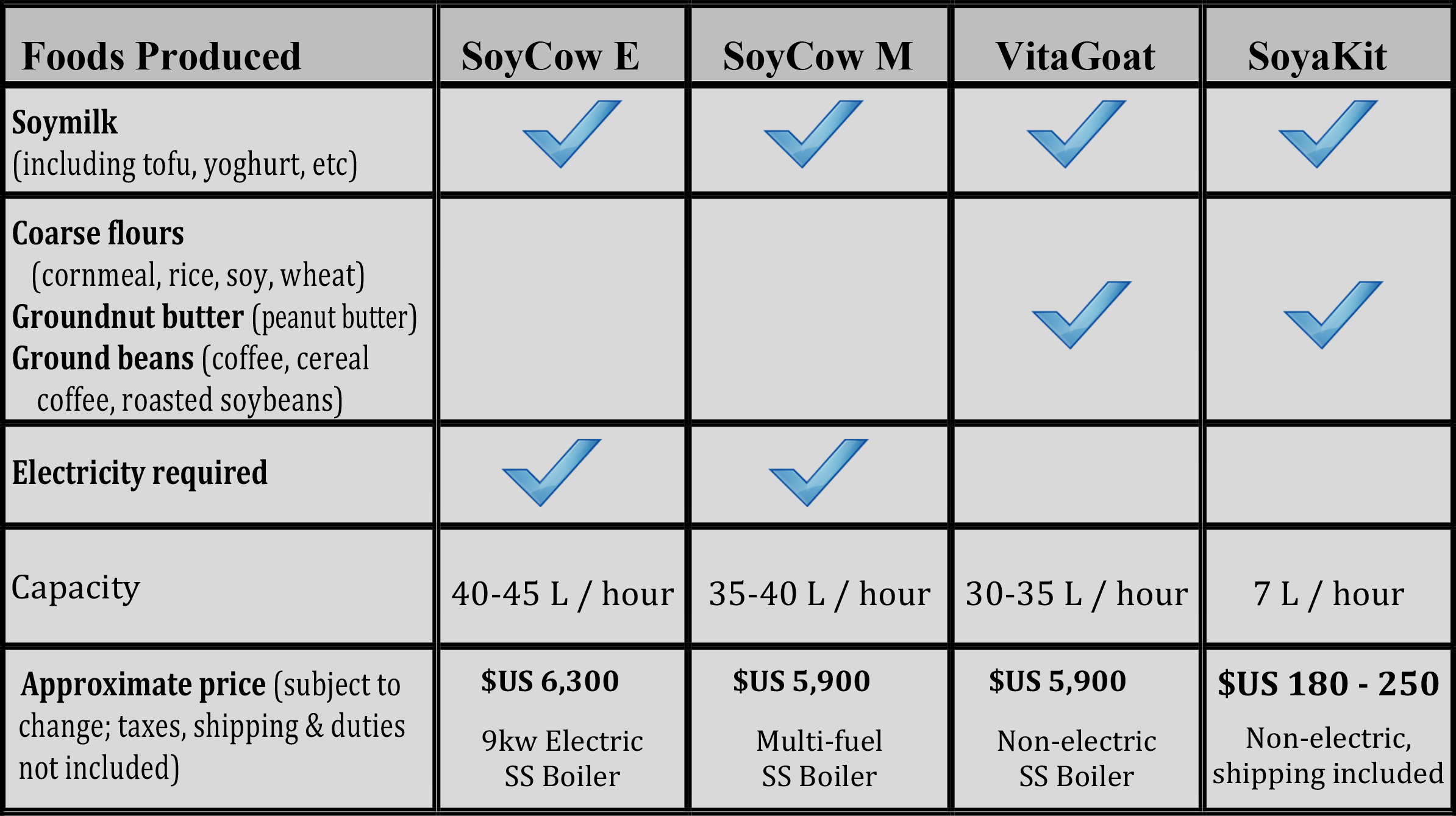

The SoyCow is an electric food processing system designed for the efficient production of soymilk and its derivatives, including beverages, tofu, soy yogurt and products using the "okara" fibre residue. There are 3 models of SoyCow:

Production capacity for the SoyCow M and E is in the range of 35 - 40 liters per hour. The SoyCow models "M" and "E" use a 20L pressure cooker and are targeted for projects which have electricity and are focused on producing soymilk and derivative products. The SoyCow 30 requires 3-phase electricity and production capacity is 80 liters / hour. Click on SoyCow 30 above for more details. The SoyCow M is a hybrid of the VitaGoat which uses an electric grinder instead of the pedal-powered cycle grinder. The designation M relates to the non-electric, Multi-fuel steam boiler included. The SoyCow E includes an automatic Electric steam boiler. Both systems share the cooker, filter press and tofu box common to the VitaGoat. The SoyCow 30 uses an 18 Kw boiler and a 40L pressure cooker, which enables a 30L batch of soymilk, hence the name SoyCow 30. For more detail on the SoyCow M and SoyCow E, see the information below.

The following process schematic briefly describes the main elements involved in producing aqueous solutions from soybeans (soymilk), but the basic process is the same for some fruits and vegetables.

Soymilk Production

Steps:

1. Soak soybeans in water

2. Discard soaking water and transfer beans beans to grinder along with fresh water.

3. Grind beans with fresh water to produce slurry.

4. Pressure-cook mixture (with steam injected from boiler).

5. Separate undissolved fiber (okara) from liquid (soymilk) with filter press.

6. Optionally make derivative soyfoods from soymilk (tofu, yogurt etc.) and okara (baked goods, patties, stews etc.).

Note:

Each soymilk "batch" takes 20 to 30 minutes to complete.

Soybean soaking time depends on soybean condition and water temperature. Typical yield is 7 L of soymilk per kg of soybeans.

SoyCow E

SoyCow M

Design and Operation:

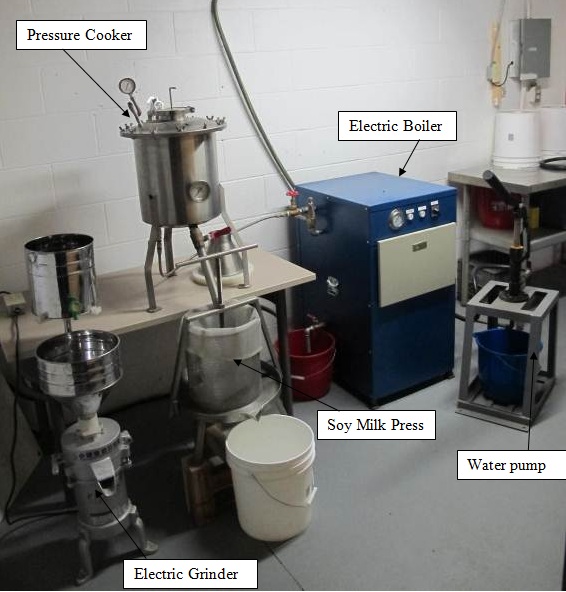

The SoyCow and VitaGoat are made from durable stainless steel and other sanitary materials and can last at least ten years if maintained properly. Installation typically takes 1 day and training another day or two. The area required for the system is modest, with a total of 10 m2 for the system operation and another 5-10m2 for storage of foods and ingredients, etc. Workers do not require special skills to operate and maintain the equipment, although it is good to have access to a person familiar with basic electricity and mechanical skills. 2 people can operate the system but more are employed if production includes value-added products. There are four main elements to each system: a grinder, a cooker (pressure vessel), a manual filter press and a steam generator (boiler). With the SoyCow, the boiler can be either automatic electric, or a multi-fuel boiler (as with the VitaGoat). The systems have a number of safety features related to the steam and pressure-cooking. They are also relatively easy and inexpensive to clean and maintain. For sanitary food processing, they require a rudimentary kitchen-like environment with good ventilation, cement or tiled floors etc. A complete site preparation guide is provided along with a detailed tech and operations guide.

Production:

The SoyCow “E” with electric boiler can achieve a slightly higher production capacity than the VitaGoat (about 40-45L per hour compared to 30-35L per hour for the VitaGoat). The SoyCow “M” with multi-fuel boiler has a capacity approximately in between these two. Any of these systems are appropriate for use in situations when the number of people served daily is in the hundreds or even a thousand. They are designed for a higher output compared to traditional cottage industry production. With a portion size of 200 to 250ml, at least five hundred people can be served a daily portion of soymilk beverage or other value-added food if the equipment is used for at least several hours’ production per day. i.e. 40 L per hour of production = 160 to 200 servings per hour In a social feeding scenario. In a seven-hour day of production up to 280 liters of bulk soymilk milk can be produced. This is equivalent to the daily output of a heard of at least 20 dairy cows in developing countries without the corresponding demand on the environment, water and feed.

Economic Benefits:

The SoyCow or VitaGoat can pay for itself within a year or two either by operation as a small business (for approx. 5 hours per day), or as the central element of a school midday-meal program, or via cost-savings realized in an institutional setting. Soya "dairy" foods (those that look like and are functionally equivalent to regular milk products) can be 50 to 75% less expensive than traditional dairy foods and still generate good income while providing a healthy, high-protein food. Each system can also generate five or more jobs, thus creating sustainable livelihoods for the community members as well.

Other videos

VitaGoat | SolarFlex | SoyaKit | Heat Pump Dryers | SoyCow

Stay Up to Date

Questions?

Request more information from matters@malnutrition.org

© 2020 Malnutrition.org | Malnutrition Matters. All Rights Reserved.